Home > Company News > EQUIPMENT MATERIAL SELECTION AGAINST FEEDSTOCK CONTAINING CHLORIDE (2)

Company News

In case of evaporators or crystallizers applied for treating feedstock containing chloride, the equipment material is suggested to be titanium due to strong corrosion of chloride.

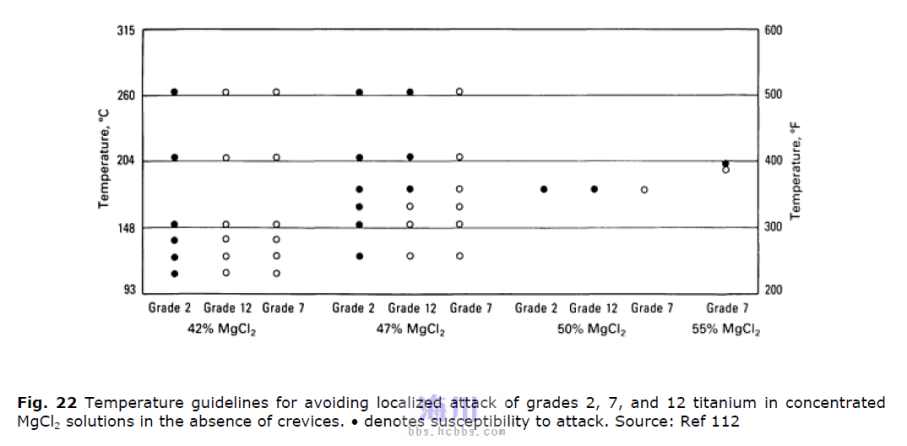

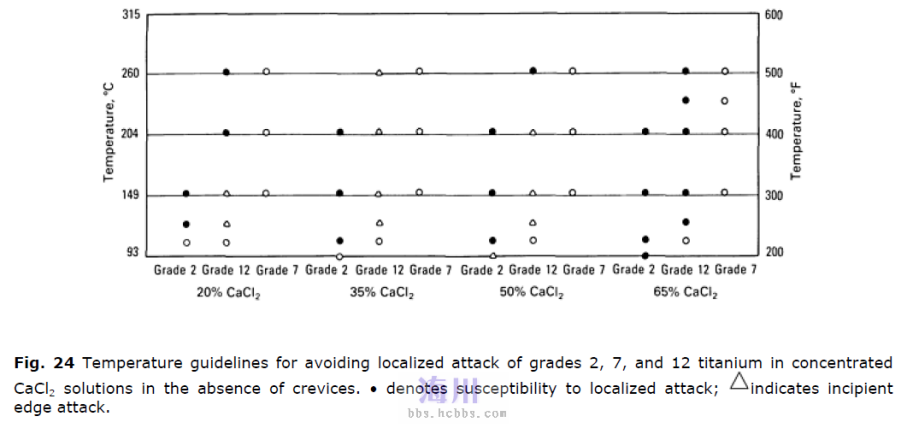

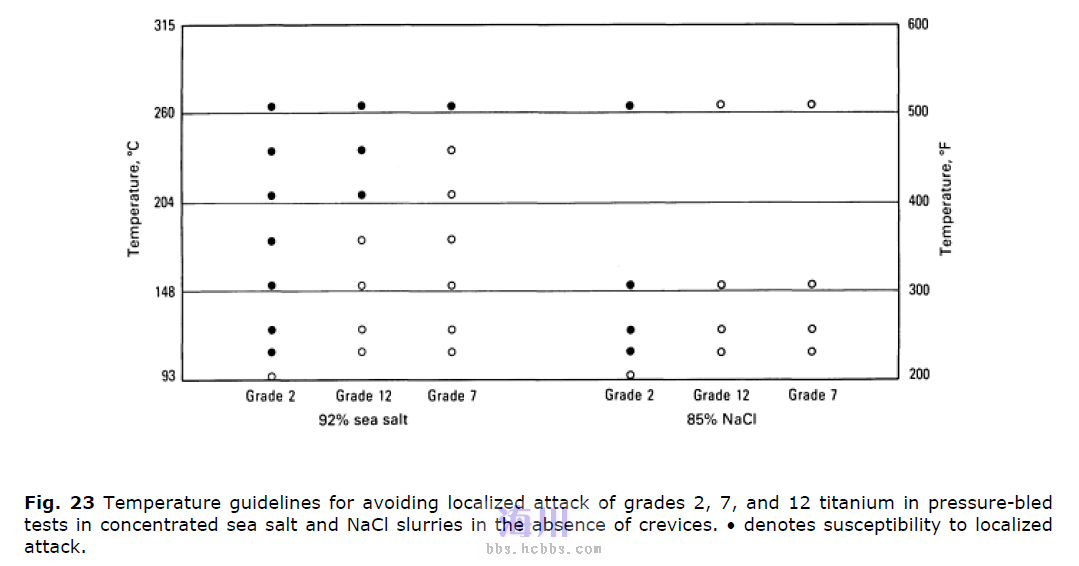

In this article, the upper limit of service temperature of pure Ti, Ti-Pd alloy( Grade 7, TA9) and the Ti-Ni-Mo alloy (Grade 12,TA10) for magnesium chloride solution, sodium chloride solution and calcium chloride solution at different concentration are shown in the following figures. There would be crevice corrosion or pitting corrosion happens when the temperature exceeds the upper limit.

Note : in the figure, the white circles represent workable; the black circles represent crevice corrosion or pitting corrosion happening easily; the white triangles represent crevice carrion happening slightly but without affecting the the normal use.

In MgCl2 solution:

In CaCl2 solution:

In NaCl solution:

It can be get that the Pi-Pd alloy and Ti-Ni-Mo have better chlorine ion resistance than pure Ti: Pi-Pd alloy (Grade 7, TA9) > Ti-Ni-Mo (Grade 12, TA10) > Pure Tiï¼Grade 2, TA2ï¼.

-

Laboratory Chemical Automatic Lifting Vacuum Rotary Evaporator

-

Digital Temperature Control Laboratory Rotary Evaporator Kit Set

-

Lab Distilling Machine Automatic Lifting Small Rotary Evaporator

-

Rotovap Extractor Distillation Vacuum Laboratory Rotary Evaporator

-

Ammonium Chloride Evaporation & Crystallization Project Completed with DMF Distillation

-

China Factory essential oil extractor essential oil distiller

-

Genyond essential oil distiller essential oil extraction supercritical extractor

-

GENYOND distillation rose essential oil extracting machine extraction maker equipment

-

CHINA Factory steam distiller for lavender essential oil extraction with logo

-

10% cut off essential aromatic oils distiller prices

-

Professional solar distiller Factory price

-

High quality steam vacuum distiller for sale

-

Professional essential oil still Factory price

-

Factory Directly sandalwood essential oil distiller original and new

-

High quality vapor compression distiller for sale

-

Factory Directly essential oil steam distillation apparatus Original and New

-

High quality short path distillation equipment for sale

-

High oil yield frankincense essential extract machine Original and New

-

Factory directly essential oil steam distillation gas machinery Original and New

-

Factory directly steam essential oil distiller unit for

-

Factory directly honey extraction machine with manufacturer

-

High oil yield herbs ethanol alcohol extractor equipment extraction filtering concentration machine for essential essence

-

Factory directly plants essential oil distiller on sale Original and New

-

Factory directly thyme essential oil distillation equipment price